VX-1 - Type 2T Tile Adhesive

VX-1 - Type 2T Tile Adhesive

product Description

VX-1 is a high-performance, polymer-modified, grey cement-based adhesive specifically designed for fixing low-porosity tiles (vitrified, semi-vitrified) and natural stones on interior and exterior floors, walls-interiors, and even swimming pools. It offers exceptional bond strength, water resistance, and ease of use. The adhesive is water-resistant and is suitable for use in showers, wet areas and swimming pools. Also, ideal for renovation (tile-over-tile) for quick & easy installation works. Its exceptional bond strength, flexibility, water resistance, and versatility make it the ideal choice for a wide range of applications.

Confirms to IS 15477: 2019 Type 2T "Adhesives for use with Ceramic, Mosaic and Stone Tiles

Note: Not recommended for direct use onto gypsum plaster (wall finishes), paint or metal. Not suitable for external wall installations, Not suitable for tiles and stones with mesh backing

Key Features And Benefits

-

Superior Bond Strength: Exceeds EN & ISO C2TE classification for shear bond strength, ensuring a durable and long-lasting installation.

-

Versatile Application: Suitable for most common substrates like concrete, masonry surfaces, existing tiles, and even terraces.

-

Water Resistant: Ideal for wet areas like showers, bathrooms, and swimming pools.

-

Easy to Use: Single-component formula requires only the addition of water for a smooth, trowelable consistency.

-

Smooth Application & Curing: Easy mixing, smooth application & better workability and achieves full strength in approximately 14 days.

-

Economical: Cost-effective solution for various tiling projects.

Suitable Substrates

Application

Method

Method of Application

Remove all Dust, Water, Oil & Sealers from Surface/ Substrate

Add 5 to 6 * Itrs water/Admix in to empty bucket

Add 20 Kg VX-1 Thin Set Adhesive in to water and mix it till attains Uniform Paste

Slake the Material for 5 to 10 minutes

Again Mix the material then take the material on notch trowel

Use flat side of the trowel and spread the adhesive uniformly

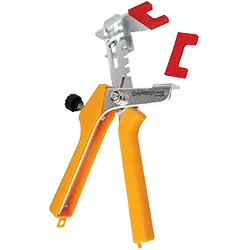

Comb the adhesive with the help of Notch trowel

Spread the material backside of the tile also (If tile size is More than 12X12)

Press the tiles firmly into position by Twisting Action

Press the tile gently with help of Wooden Hammer to make uniform tile surface

Clean the Tile surface with wet Cloth

For Foot Traffic wait up to 24 Hrs

After 24 Hrs you can do the grouting

reliable

Technical Data

(Type-2)

| Property | Value |

|---|---|

| Density | 1.7 kg / litre approx. |

| Pot Life | 120 Minutes Approx |

| Open Time | 30 minutes Approx |

| Adjustability | 30 minutes Approx |

| Setting Time | Approx. 1 Day |

| Full Strength | Approx. 14 Days |

| Tensile Strength | >1.20 N/mm² |

| Shear Strength | >1.25 N/mm² |

data

IS Data

| Property: Test method | Requirement | Typical Values |

|---|---|---|

| Tensile Adhesion | ||

| Wet Conditions - Annex A (Clause 5.1) | Minimum 1.00 N/mm² | 1.15-1.25 N/mm² |

| Dry Condition - Annex A (Clause 5.1) | Minimum 1.00 N/mm² | 1.15-1.25 N/mm² |

| Shear Adhesion | ||

| Dry Condition – Annex B (Clause 5.2) | Minimum 1.25 N/mm² | 1.30–1.35 N/mm² |

| Heat Ageing - Annex B (Clause 5.2) | Minimum 1.00 N/mm² | 1.05-1.15 N/mm² |

| Wet Condition – Annex B (Clause 5.2) | Minimum 1.00 N/mm² | 1.10-1.20 N/mm² |

| Slip Resistance | ||

| Slip resistance – Annex B (Clause 5.2) | ≤ 0.5 mm | 0.35 mm |

CERTIFICATIONS :

-

Confirms to IS 15477: 2019 Type 2T “Adhesives for use with Ceramic, Mosaic and Stone Tiles”

-

Confirms to EN 12004 / ISO 13007 and is an improved cementitious adhesive (C2) with slip resistance (T) and Extended Open time (E) of class C2TE

PACKAGING : 20 kg bag (Available in Grey and White (With the name of VX-2))

COVERAGE :

-

Approx. 55–60 sq. ft. per 20 kg bag (using a 6mm x 6mm notched trowel for a 3mm bed)

-

1.2 kg/m² per mm of thickness (coverage may vary)

Disclaimer: This technical data sheet is provided for informational purposes only. The information contained herein is based on our technical knowledge and experience. However, due to variations in field conditions, we recommend conducting preliminary tests to ensure product suitability for a specific application.

Installation

Installation

Instructions

Surface Preparation

-

Ensure a clean, sound substrate between 40°F (4°C) and 104°F (40°C), free from dirt, oil, grease, paint, laitance, and sealers.

-

Level uneven surfaces with a screed or plaster.

-

Dampen dusty or dry concrete before installation. New concrete must be cured for at least 28 days.

-

Incorporate expansion joints matching substrate joints.

-

Use Gresbond PUA-100 for wood substrates.

Mixing

-

Pour clean water into a mixing bowl.

-

Gradually add VX-1 powder (5 - 5.5 liters per 20 kg).

-

Mix until smooth and trowelable consistency. Let it slake for 5 minutes.

-

Remix before applying with the appropriate trowel size.

-

For large format tiles or exterior applications, consult Gresbond technical services.

Application

-

Apply adhesive with the flat side of the trowel, ensuring good contact.

-

Use the appropriate notched trowel to ensure full tile bedding.

-

Comb additional adhesive with the notched trowel to cover the backside of the tile. Spread only enough for 10 minutes of working time.

-

Back-butter large format tiles for better support.

-

Firmly press tiles into the wet adhesive and adjust level.

-

Check for complete adhesive coverage on the back of the tile periodically.

-

Use spacers for grout joints as per recommendations. Remove spacers after the adhesive sets.

-

If the adhesive skins over, remove and replace with fresh mix.

-

For some natural stones, apply suitable sealers on all sides.

-

Clean excess adhesive from tiles and joints while fresh.

Precautions & Note

-

Always add powder to water. Do not add excess water.

-

Do not add sand or cement on-site.

-

Not recommended for wet screeds or uneven surfaces exceeding 12mm.

-

Protect from rain and foot traffic for 24 hours.

-

Leave gaps between tiles and fill with Gresbond tile grout.

-

For installations exceeding 3 meters in height, consult a professional about additional mechanical fasteners.

-

Not suitable for gypsum plaster, fiber cement boards, plywood, metal, plastics, or deformable surfaces. Use Gresbond PUA-100 for such applications.

- This adhesive is not a replacement for waterproofing coatings in wet areas. Use a suitable waterproofing membrane before tiling.

- Not recommended for artificial/engineered stone, composites, or metal tiles. Use Gresbond PUA-100 for these materials.

Limitation

-

Trowel Selection: The size of the notched trowel will depend on the size and type of tile you're installing. For larger tiles or uneven substrates, a bigger notch size is recommended to ensure full coverage.

-

Weather Conditions: While VX-1 can be used for exterior applications, extreme heat or cold can affect drying times. Always check the weather forecast and adjust working practices accordingly.

-

Substrate Preparation: Proper surface preparation is crucial for a successful tile installation. Don't underestimate the importance of a clean, sound, and level substrate.

-

Working Time: Once mixed, VX-1 has a working time of about 15–20 minutes. It's important to work efficiently and avoid mixing large quantities at once to prevent wastage.

Grouting

-

Begin grouting after 24 hours at 70°F (21°C) using Gresbond's KE-100 series grout or unsanded grout.

By following the instructions in this data sheet and considering these additional tips, you can achieve a professional and long-lasting tile installation using VX-1 Type 2 T Tile Adhesive.

Frequently Asked Questions

What is VX1 Tile Adhesive used for?

This is used to fix tiles on walls and floors, including ceramic, vitrified, and large wall tiles, for residential and commercial purposes. Its VX-1 name stands due to its compatibility with vitrified tiles with zero porosity.

Can VX1 Tile Adhesive be used in wet areas like bathrooms?

Yes, it is suitable for use in wet areas such as bathrooms. It provides a solid and durable bond and prevents seepage and leakage.

How do you apply VX1 Tile Adhesive on walls?

Apply a VX1 Tile Adhesive paste layer with a notched trowel to ensure even thickness and proper coverage for gluing wall tiles. Apply a coating on the substrate and large-format wall tiles to provide a long-lasting finish.

What makes VX1 Tile Adhesive the best choice for floor tiles?

It is made of polymer-modified grey cement and offers premium quality, strong adhesion, and durability, making it the best choice for laying floor tiles.

Is VX-1 Tile Adhesive suitable for tile-on-tile application?

It is formulated for heavy-duty applications for fixing vitrified and large-size tiles. It also works effectively for tile-on-tile applications, ensuring strong bonding and adhesion. With waterproofing quality, it is based on fixing large-format tiles on dull, old-fashioned tiles.

What is the recommended thickness for the VX-1 Tile Adhesive mixture?

Typically, the thickness is between 3-10 mm, depending on the type of tile and substrate. Only a professional may apply the right thickness after checking the substrate quality and tiles used.

How does VX1 Tile Adhesive differ from traditional cement glue?

VX1 Tile Adhesive is made of modified polymer-based cement, offering superior bonding strength, flexibility, and ease of use compared to traditional cement glue, making it a premium choice. Traditional cement paste is hard to mix and takes too much time to apply.

Where can I buy VX-1 Tile Adhesive in India?

It is available at leading hardware stores and authorized Gresbind by Kajaria dealers in India. Visit the website, select the Where to Buy section, select your nearby location, and locate the nearby Gresbond dealer to purchase VX-1 Tile Adhesive. You may also Google to explore the nearby Gresbond Dealers in your area.

What is the coverage area of VX-1 Tile Adhesive per kg?

The coverage area of VX1 Tile Adhesive per kg varies based on application thickness and tile size but typically covers approximately 4-5 square meters per 20 kg bag.

Is VX-1 Tile Adhesive suitable for fixing large wall tiles?

Yes, it is designed with premium-quality chemical and polymer-modified cement to provide strong adhesion and support for securely fixing large wall tiles.