How many types of Grouts are Available in the Market? Which Grout is Suitable for My Tile?

How many types of Grouts are Available in the Market? Which Grout is Suitable for My Tile?

Looking to install your tiles and finding better solutions to fill the gaps on walls and floor? Here we are with a small guide on the types of grouts, differences between various types of grouts, tips to choose the best grout for your tiling wall & floors.

When installing tiles, grout is essential for both practical and aesthetic reasons. Selecting the appropriate grout type is crucial to guarantee endurance, resilience, and preservation of the overall look of your tiled surface. Although tile usually receives more attention, grout can sometimes take precedence.

Choosing the appropriate grout type is essential, as many varieties are available. However, how do you make a decision? Your decision will depend on your priorities and previous grout-related difficulties.

What is Grout:

Grout is a filler and structural support material made of cement or epoxy between tiles. It increases the overall stability of the tiled surface, reduces tile movement, and stops moisture from penetrating.

Types of Grout:

- Cement-Based Grout

- Epoxy Grout

- Furans Grout

- Sanded Grout

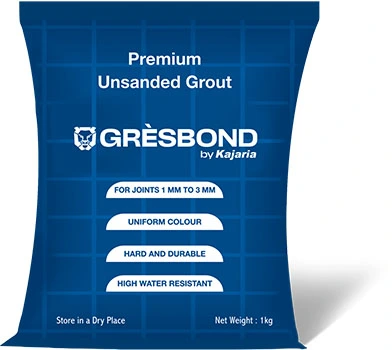

- Unsanded Grout

- High-Performance & Polymer Cement Grout

- 100% solids Epoxy

- Conventional grout, which is commonly used

- Made up of additives, sand, and Portland cement

- Both sanded and unsanded versions are available

- Compatible with the majority of porcelain, ceramic, and natural stone tiles

- Provides cost, adaptability, and simplicity of use

- Needs must be sealed to stop water absorption and discoloration

- Because of the possibility of scratches, using highly polished or glass tiles is not advised.

- Affordability: Compared to other grout forms, cement grout is typically less expensive, making it a viable choice for various applications.

- Ease of Application: Cement grout is comparatively simple to mix and apply, which makes it appropriate for do-it-yourself jobs or novice installations.

- Natural Appearance: Cement grout frequently has a more conventional and natural appearance, which some design aesthetics may find appealing.

- Availability: Buying cement grout is handy because it's readily available at most home improvement stores.

- Porosity: If cement grout is not correctly sealed, it can become stained and allow water to seep in. Over time, this may result in damage and discoloration.

- Care: To maintain the tiled surface looking its best overall, discoloration and water damage must be avoided with sealing and routine care.

- Limited Durability: Especially in high-traffic areas, cement grout is more prone to cracking or deteriorating over time than epoxy grout.

- Limited Color Options: Compared to other grout kinds, cement grout usually offers fewer color options, reducing design flexibility.

- Prone to Cracking: As cement grout dries, it may shrink and fracture, particularly in broader grout joints. This might allow water to seep in and do additional harm to the tiled surface.

- High-tech, long-lasting grout choice

- Made using fillers and epoxy resins

- Impervious to dampness, cracking, stains, and chemicals

- Perfect for commercial settings, damp situations, and high-traffic areas

- Comes in a variety of colors, including vivid tones

- Necessitates careful application and removal

- Costlier than grout made of cement

- Because it may discolor some types of natural stone tiles, it is not advised to use it with them.

- Exceptional Durability: Epoxy grout is long-lasting and resistant to stains, shrinking, and breaking.

- Waterproof: Because epoxy grout is non-porous, moisture damage and infiltration are unlikely. This makes it perfect for moist spaces like kitchens, bathrooms, and showers.

- Stain Resistance: Epoxy grout is relatively impervious to stains from chemicals, water, and other materials, which makes it simple to keep clean.

- Color Stability: Epoxy grout offers outstanding color retention and consistency over time, retaining its color and look.

- Broad Color Selection: Epoxy grout comes in various hues, giving designers more creative freedom and personalization.

- Cost: The installation of tiles may cost more overall because epoxy grout is usually more expensive than cement-based grout.

- Complex Application: Unlike cement grout, epoxy grout has a shorter working time but requires precise mixing and application. This could make DIY installation more difficult.

- Hard to Remove: Epoxy grout can be challenging to remove from tile surfaces once it has been set, which makes tile replacements or repairs more complex.

- Potentially Toxic: Prolonged exposure to epoxy resin and hardeners may cause skin irritation or allergic responses in certain people. Epoxy grout contains compounds that may release unpleasant scents during installation.

- Not Suitable for All Tiles: Because epoxy grout can be challenging to remove from rough or porous surfaces, it might only be appropriate for some tile varieties, including natural stone tiles.

- Highly resilient and environmentally friendly grout

- Composed of filler components and furan resin

- Provides outstanding heat stability and chemical resistance

- Fit for use in food processing facilities, chemical plants, and industrial environments

- Needs protective clothing and specific installation techniques

- Fewer color possibilities than epoxy and cement-based grouts

- Increased price as a result of specific needs for application and formulation

- Chemical Resistance: Furans grout has a high resistance level to various substances, such as solvents, acids, and alkalis. Because of this, it is perfect for usage in industrial settings, chemical processing facilities, and other establishments where workers frequently come into contact with hazardous chemicals.

- Resistance to Extremes in Temperature: Furans grout is resistant to extremes in temperature without deteriorating or losing its structural integrity. Because of this, it is appropriate for settings with frequent temperature changes, including outdoor installations or establishments with high-temperature operations.

- Low Permeability: Due to its low permeability, Furans grout resists moisture damage and water infiltration. This qualifies it for usage in moist settings, including fountains, swimming pools, and wastewater treatment plants.

- High Strength: Furans grout is renowned for having a high compressive strength, which offers exceptional structural stability and load-bearing capacity. Because of this, it may be used for demanding tasks like installing large machines and industrial flooring.

- Cost: Furans grout tends to be more costly than conventional cement-based grouts, which could raise the project's final cost.

- Difficult Application: Compared to cement-based grouts, furans grout may have a shorter working period but requires careful mixing and application. It could take specific knowledge or experience to implement this properly.

- Limited Availability: Compared to other grout forms, furans grout might be less widely available, and finding suppliers or contractors knowledgeable about its application might be more challenging.

- Odor: When furans grout is mixed and applied, it may release intense aromas that are disagreeable and necessitate adequate ventilation in enclosed places.

- Sanded grout: Composed of cement and grit sizes of at least 1/8"

- Grout without sanding: cement grout with grit less than 1/8"

- Sanded grout is suitable for broader grout joints, typically between 1/8" and 5/8" and occasionally up to 1". It adds strength and structure to the grout.

- In domestic settings, both sanded and unsanded grouts are frequently utilized.

- Greater Stability and Strength: Sanded grout is perfect for larger grout joints and high-traffic areas because it contains sand particles, which give it extra stability and strength.

- Lessened Shrinkage: Sand particles aid in minimizing shrinkage during the drying process, which lessens the possibility that cracks will eventually appear.

- Increased Stability: Sanded grout is easier to work with, especially on vertical surfaces or uneven tile installations, because it is less likely to sink or slump when applied.

- Improved Bonding: Sanded grout's rough texture promotes improved adherence to the substrate and tile surfaces, resulting in a more robust and longer-lasting bond.

- Scratching: During application or cleaning, the sand particles in sanded grout may cause scratches on fragile tile surfaces, such as glazed ceramic or glass tiles.

- Limited Application: Sand particles might make filling small spaces difficult and perhaps provide an uneven or harsh finish, so sanded grout is not recommended for grout joints smaller than 1/8 inch.

- Potential Staining: Sanded grout's porous nature makes it more prone to dirt and spill stains, necessitating routine sealing and upkeep to maintain its aesthetic.

Tile applications with grout joints between 1/16" and 1/8" narrower are often better suited for unsanded grout.

Pros- Suitable for Narrow Joints: Unsanded grout offers a smooth and consistent finish in confined locations where sanded grout may be challenging to apply. It is perfect for grout joints smaller than 1/8 inch.

- Smooth Texture: Unsanded grout has a smoother texture due to the lack of sand particles, which makes it simpler to apply and clean—especially on sensitive or smooth tile surfaces.

- Less prone to Scratching: Unsanded grout works better with softer or more fragile tiles since it is less likely to scratch or harm sensitive materials.

- Decreased Strength: Because unsanded grout does not have the extra strength sand particles have, it is not as appropriate for larger grout joints and high-traffic areas where more stability is required.

- More significant Shrinkage: During the drying process, unsanded grout tends to shrink more, which raises the possibility of cracks forming over time, especially in larger grout joints.

- Limited adherence: The smooth texture of unsanded grout can lead to less successful bonding, particularly on vertical surfaces or uneven tile installations. For best adherence, appropriate surface preparation is necessary.

- Tighter requirements for shrinkage, water absorption, and strength must be met by drains intended for high-traffic residential environments or general commercial spaces.

- It comes in two varieties: sanded and unsanded.

- Today's cement grout includes more polymers, offering advantages over plastics and high-performance grout.

- Compared to conventional cement grouts, polymers in the grout activate when they come into contact with water, increasing their strength and water resistance.

- Provides improved resistance to abrasion and chemicals, attributes that non-high-performance grouts do not have

- Superior color consistency and resistance to efflorescence - a frequent problem with cement

- It's often recommended for most individuals to opt for high-performance or epoxy grouts, as they offer superior performance and durability

- Increased Durability: Compared to conventional cement-based grouts, high-performance and polymer cement grouts offer more excellent durability. They are perfect for high-traffic areas and damp situations since they resist shrinking, cracking, and discoloration.

- Water Resistance: The outstanding water resistance of these grouts aids in preventing moisture damage and water penetration. They can, therefore, be used in toilets, showers, and other locations where there is a chance of water exposure.

- Resistance: Polymer cement and high-performance grouts are very resistant to stains from chemicals, water, and other materials. They look better for longer since they are simpler to keep clean and maintain.

- Improved Color Consistency: Compared to conventional grouts, these grouts provide a more uniform color throughout the tiled surface.

- Flexibility: Some high-performance and polymer cement grouts offer greater flexibility, allowing for slight movement of the tiled surface without cracking or compromising the grout's integrity.

- Cost: High-performance and polymer cement grouts are usually more costly than conventional cement-based grouts. The higher starting cost may impact the project budget as a whole.

- Complexity of Application: These could call for more specialized application methods than conventional grouts. Optimal performance and longevity are contingent upon the appropriate mixture and application.

- Limited Availability: High-performance and polymer cement grouts could be more challenging to locate and acquire than standard grouts.

- Curing Time: Compared to conventional grouts, some high-performance and polymer cement grouts may require longer curing times. This may cause the installation procedure to drag on and delay the tiled area's use.

- Potential Allergies: Some individuals may be sensitive to the chemicals used in high-performance and polymer cement grouts, leading to allergic reactions or respiratory issues during installation. Proper ventilation is essential when working with these products.

- Perfect for harsh settings, including industrial kitchens, dairy farms, and meat processing facilities

- Strong chemicals are frequently used daily in these environments and sometimes left on the floor without being rinsed.

- When it comes to performance, 100% solids epoxy outperforms conventional epoxy.

- Unlike traditional epoxy choices, it is fast-curing and excels in many ways.

- Able to withstand high temperatures, making it appropriate for hotter settings.

- Offers improved chemical resistance, guaranteeing longevity even in challenging circumstances.

- Exceptional Durability: Grout made entirely of solid epoxy is highly resilient to discoloration, shrinking, and cracking. Even in high-traffic areas, it offers a durable tile installation solution.

- Waterproof: Because this particular kind of epoxy grout is non-porous, it is waterproof. It works well to stop moisture damage and water seepage. Thus, it's appropriate for moist areas like fountains, swimming pools, and showers.

- Stain Resistance: Grout made entirely of solid epoxy is very resistant to stains from chemicals, water, and other materials. It is simple to keep clean and maintain to look great for many years.

- Color Stability: Epoxy grout offers outstanding color retention and consistency over time, retaining its color and look. The tiled surface appears homogeneous because it doesn't turn yellow or fade.

- Chemical Resistance: This grout is waterproof to various substances, such as solvents, acids, and alkalis. It can be used in industrial environments and places where people frequently encounter hazardous chemicals.

- Cost: Compared to other grout kinds, 100% solids epoxy grout is usually more expensive. The higher starting cost may impact the project budget as a whole.

- Complexity of Application: Compared to cement-based grouts, this grout has a shorter working period but requires precise mixing and application. For best results and longevity, preparation and application must be done correctly.

- Potentially Toxic: During installation, chemicals in 100% solids epoxy grout may release unpleasant odors. Some people may experience allergic reactions or skin irritation after prolonged epoxy resin and hardeners exposure. When using these goods, enough ventilation is required.

- Difficult Removal: 100% solids epoxy grout can be challenging to scrape off tile surfaces once set. Tile replacements and repairs can be complex and require specific equipment and methods

- Not Suitable for All Tiles: Because 100% solid epoxy grout can be challenging to remove from rough or porous surfaces, it might only be appropriate for some tile varieties, including natural stone tiles. Before installation, compatibility with particular tile materials should be taken into account.

Several considerations, such as the type of tile, the location, the amount of foot traffic anticipated, and your aesthetic tastes, will determine which grout is best for your tile. To aid in your decision-making process, take into account the following:

- Grouts compatible with sealants are needed to stop moisture from penetrating and discoloring porous tiles like natural stone and unglazed ceramic.

- To prevent damage and scratches, unsanded grouts work best when used with glass tiles and highly polished surfaces.

- Epoxy grout offers exceptional water resistance and durability for damp spaces, including kitchens, bathrooms, and swimming pools.

- Epoxy or furans grout, which endures severe use and regular cleaning, is advantageous in high-traffic areas.

- Cement-based grout offers a classic, textured appearance suitable for rustic or traditional design schemes.

- Epoxy grout provides a sleek, modern look with its uniform finish and wide range of color options

- Furans grout may be preferred for industrial or utilitarian spaces, prioritizing function over aesthetics.

Type of Tile:

Location:

Aesthetic Preferences:

| Feature | Cement Grout | Epoxy Grout |

| Composition | Cement, sand, water | Epoxy resin, hardener, fillers |

| Usage | Ceramic, porcelain, stone tiles | Various tile types |

| Sealing Required | Yes | No |

| Stain Resistance | Poor | Excellent |

| Water Resistance | Fair | Excellent |

| Chemical Resistance | Limited | Excellent |

| Cost | Less Expensive | More Expensive |

| Color Options | Limited | Wide Range |

| Cracking | Prone | Resistant |

| Durability | Moderate | High |

Selecting the appropriate grout is crucial for your tile installation project to be successful. When choosing grout, consider elements including tile kind, location, and aesthetic preferences. Furans, epoxy, and cement-based grout are alternatives. Each variety satisfies various uses and design specifications while providing unique qualities and benefits. You can create a tiled surface that lasts a long time and improves the appearance and use of your space by being aware of the characteristics and applications of each type of grout.However, because there are now more alternatives available, a lot of builders and homeowners are moving away from traditional grouts.